【R128】应用开发案例——适配SPI驱动ST7789V2.4寸LCD

-

基于R128-S2设计的全套开发板已上线淘宝百问网韦东山老师个人店进行售卖,包含黑色的DshanMCU-R128s2-R16N16模组和全套的DshanMCU-R128s2-DEVKIT。

- DshanMCU-R128s2-R16N16模组:39.9元

- DshanMCU-R128s2-DEVKIT开发板:59.9元

R128开发板购买链接:https://item.taobao.com/item.htm?spm=a21n57.1.0.0.46b0523cMfarLo&id=736154682975&ns=1&abbucket=5#detail

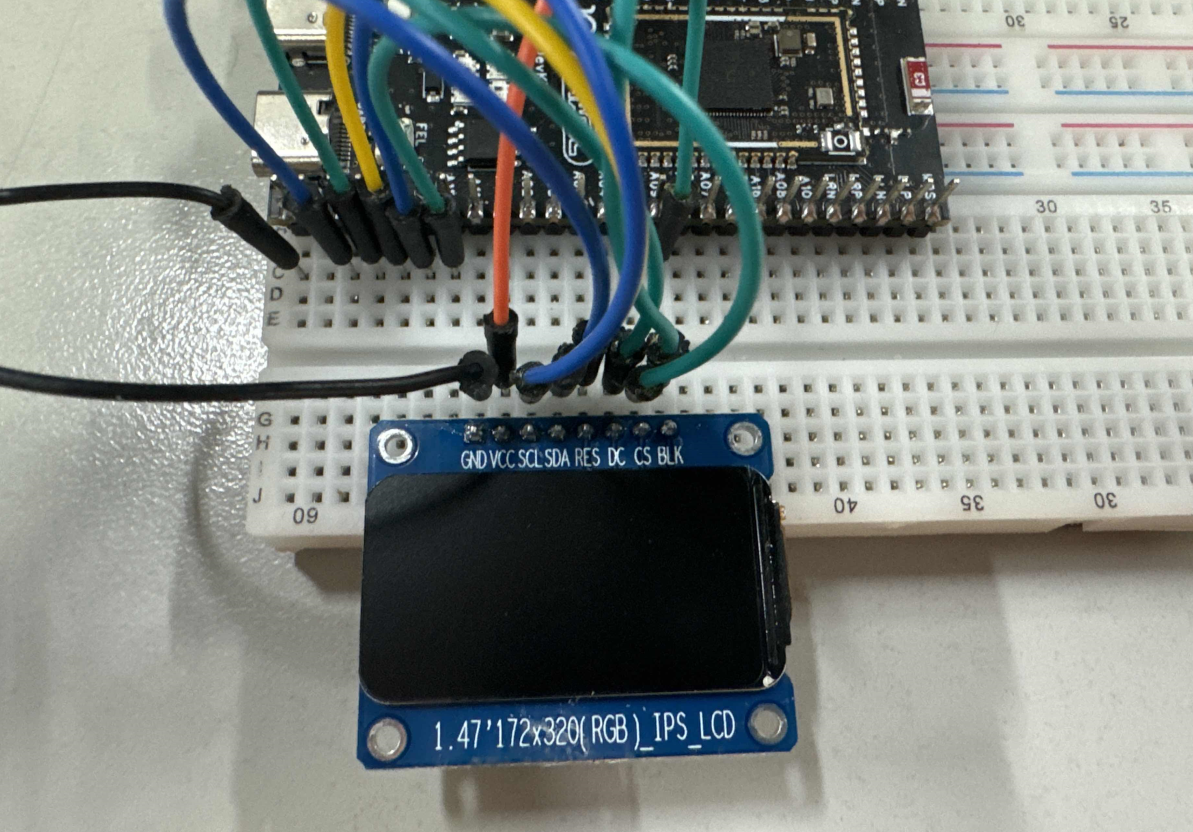

SPI驱动ST7789V1.47寸LCD

R128 平台提供了 SPI DBI 的 SPI TFT 接口,具有如下特点:

- Supports DBI Type C 3 Line/4 Line Interface Mode

- Supports 2 Data Lane Interface Mode

- Supports data source from CPU or DMA

- Supports RGB111/444/565/666/888 video format

- Maximum resolution of RGB666 240 x 320@30Hz with single data lane

- Maximum resolution of RGB888 240 x 320@60Hz or 320 x 480@30Hz with dual data lane

- Supports tearing effect

- Supports software flexible control video frame rate

同时,提供了 SPILCD 驱动框架以供 SPI 屏幕使用。

此次适配的SPI屏为

ZJY147S0800TG01,使用的是 SPI 进行驱动。

引脚配置如下:

R128 Devkit TFT 模块 PA12 CS PA13 SCL PA18 SDA PA9 BLK PA20 RES PA19 DC 3V3 VCC GND GND 载入方案

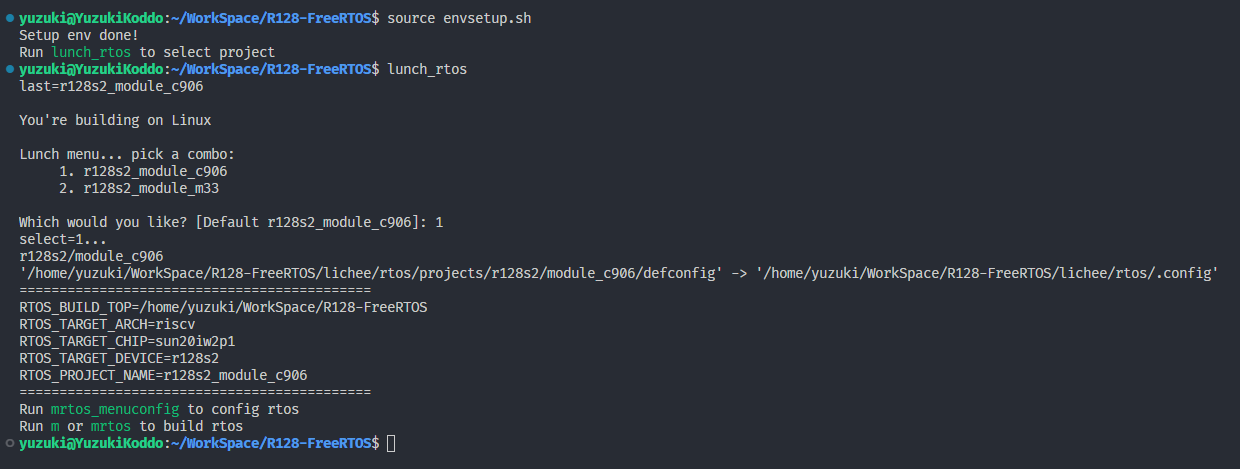

我们使用的开发板是 R128-Devkit,需要开发 C906 核心的应用程序,所以载入方案选择

r128s2_module_c906$ source envsetup.sh $ lunch_rtos 1

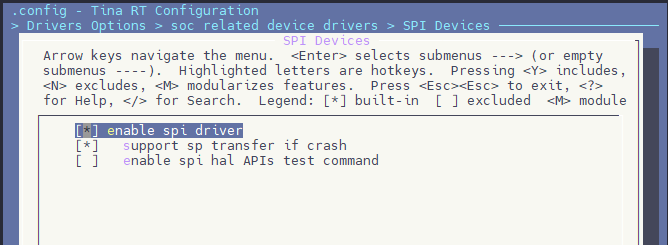

设置 SPI 驱动

屏幕使用的是SPI驱动,所以需要勾选SPI驱动,运行

mrtos_menuconfig进入配置页面。前往下列地址找到SPI DevicesDrivers Options ---> soc related device drivers ---> SPI Devices ---> -*- enable spi driver

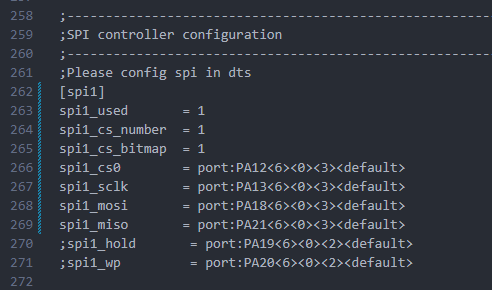

配置 SPI 引脚

打开你喜欢的编辑器,修改文件:

board/r128s2/module/configs/sys_config.fex,在这里我们不需要用到 SPI HOLD与SPI WP引脚,注释掉即可。;---------------------------------------------------------------------------------- ;SPI controller configuration ;---------------------------------------------------------------------------------- ;Please config spi in dts [spi1] spi1_used = 1 spi1_cs_number = 1 spi1_cs_bitmap = 1 spi1_cs0 = port:PA12<6><0><3><default> spi1_sclk = port:PA13<6><0><3><default> spi1_mosi = port:PA18<6><0><3><default> spi1_miso = port:PA21<6><0><3><default> ;spi1_hold = port:PA19<6><0><2><default> ;spi1_wp = port:PA20<6><0><2><default>

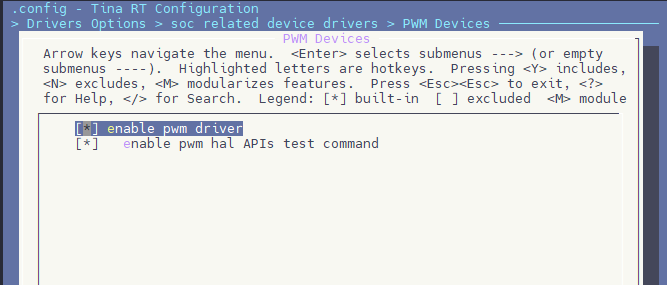

设置 PWM 驱动

屏幕背光使用的是PWM驱动,所以需要勾选PWM驱动,运行

mrtos_menuconfig进入配置页面。前往下列地址找到PWM DevicesDrivers Options ---> soc related device drivers ---> PWM Devices ---> -*- enable pwm driver

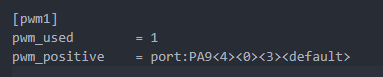

配置 PWM 引脚

打开你喜欢的编辑器,修改文件:

board/r128s2/module/configs/sys_config.fex,增加 PWM1 节点[pwm1] pwm_used = 1 pwm_positive = port:PA9<4><0><3><default>

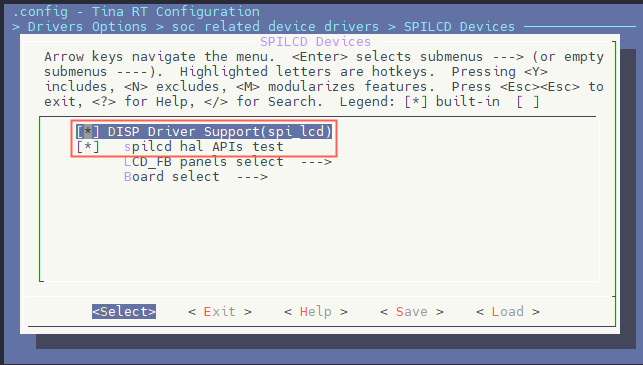

设置 SPI LCD 驱动

SPI LCD 由专门的驱动管理。运行

mrtos_menuconfig进入配置页面。前往下列地址找到SPILCD Devices,注意同时勾选spilcd hal APIs test方便测试使用。Drivers Options ---> soc related device drivers ---> [*] DISP Driver Support(spi_lcd) [*] spilcd hal APIs test

编写 SPI LCD 显示屏驱动

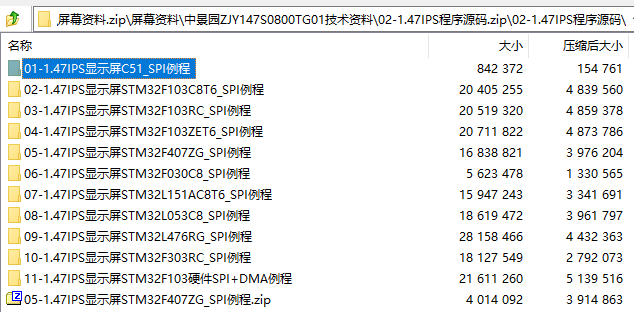

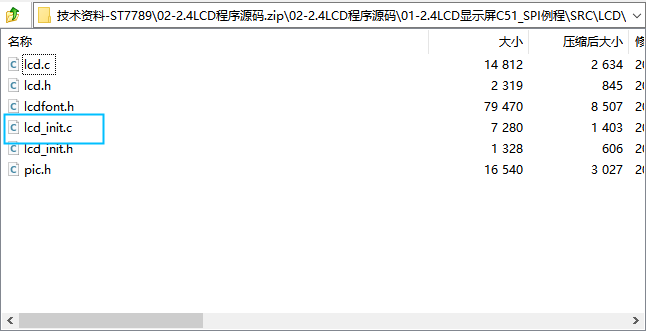

获取屏幕初始化序列

首先询问屏厂提供驱动源码

)

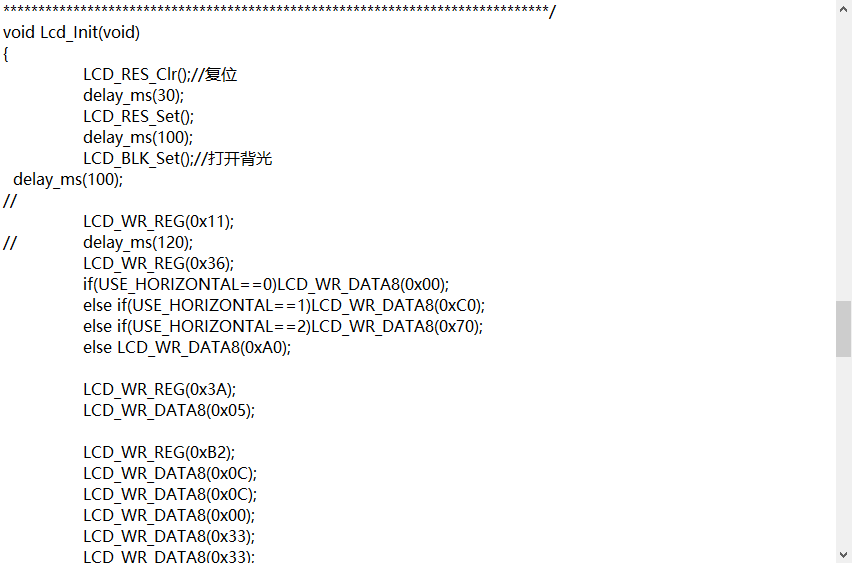

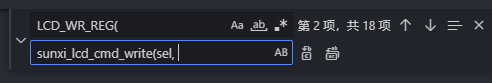

)找到 LCD 的初始化序列代码

找到屏幕初始化的源码

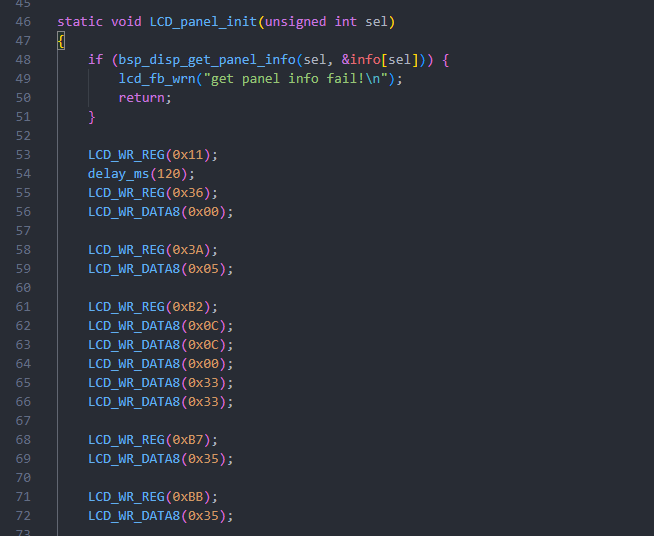

整理后的初始化代码如下:

LCD_WR_REG(0x11); delay_ms(120); LCD_WR_REG(0x36); LCD_WR_DATA8(0x00); LCD_WR_REG(0x3A); LCD_WR_DATA8(0x05); LCD_WR_REG(0xB2); LCD_WR_DATA8(0x0C); LCD_WR_DATA8(0x0C); LCD_WR_DATA8(0x00); LCD_WR_DATA8(0x33); LCD_WR_DATA8(0x33); LCD_WR_REG(0xB7); LCD_WR_DATA8(0x35); LCD_WR_REG(0xBB); LCD_WR_DATA8(0x35); LCD_WR_REG(0xC0); LCD_WR_DATA8(0x2C); LCD_WR_REG(0xC2); LCD_WR_DATA8(0x01); LCD_WR_REG(0xC3); LCD_WR_DATA8(0x13); LCD_WR_REG(0xC4); LCD_WR_DATA8(0x20); LCD_WR_REG(0xC6); LCD_WR_DATA8(0x0F); LCD_WR_REG(0xD0); LCD_WR_DATA8(0xA4); LCD_WR_DATA8(0xA1); LCD_WR_REG(0xD6); LCD_WR_DATA8(0xA1); LCD_WR_REG(0xE0); LCD_WR_DATA8(0xF0); LCD_WR_DATA8(0x00); LCD_WR_DATA8(0x04); LCD_WR_DATA8(0x04); LCD_WR_DATA8(0x04); LCD_WR_DATA8(0x05); LCD_WR_DATA8(0x29); LCD_WR_DATA8(0x33); LCD_WR_DATA8(0x3E); LCD_WR_DATA8(0x38); LCD_WR_DATA8(0x12); LCD_WR_DATA8(0x12); LCD_WR_DATA8(0x28); LCD_WR_DATA8(0x30); LCD_WR_REG(0xE1); LCD_WR_DATA8(0xF0); LCD_WR_DATA8(0x07); LCD_WR_DATA8(0x0A); LCD_WR_DATA8(0x0D); LCD_WR_DATA8(0x0B); LCD_WR_DATA8(0x07); LCD_WR_DATA8(0x28); LCD_WR_DATA8(0x33); LCD_WR_DATA8(0x3E); LCD_WR_DATA8(0x36); LCD_WR_DATA8(0x14); LCD_WR_DATA8(0x14); LCD_WR_DATA8(0x29); LCD_WR_DATA8(0x32); LCD_WR_REG(0x21); LCD_WR_REG(0x11); delay_ms(120); LCD_WR_REG(0x29);用现成驱动改写 SPI LCD 驱动

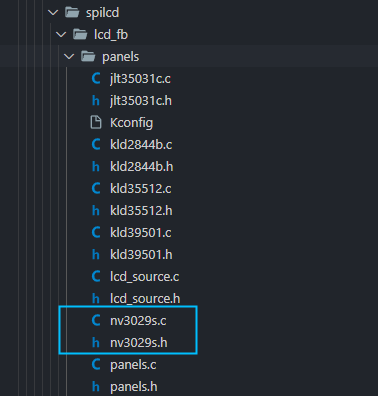

选择一个现成的 SPI LCD 改写即可,这里选择

nv3029s.c驱动来修改

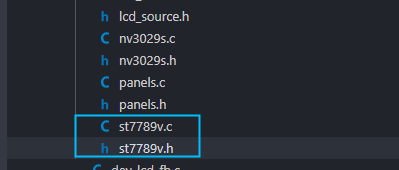

复制这两个驱动,重命名为

st7789v.c

先编辑

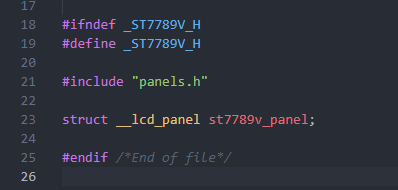

st7789v.h将nv3029s改成st7789v

#ifndef _ST7789V_H #define _ST7789V_H #include "panels.h" struct __lcd_panel st7789v_panel; #endif /*End of file*/编辑

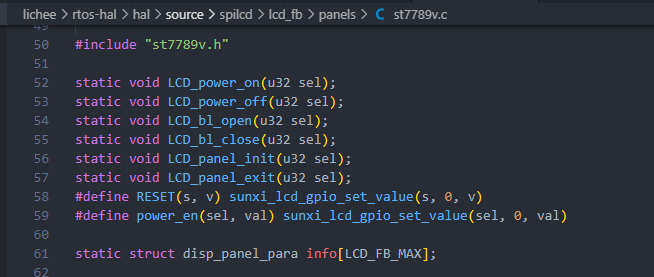

st7789v.c将nv3029s改成st7789v

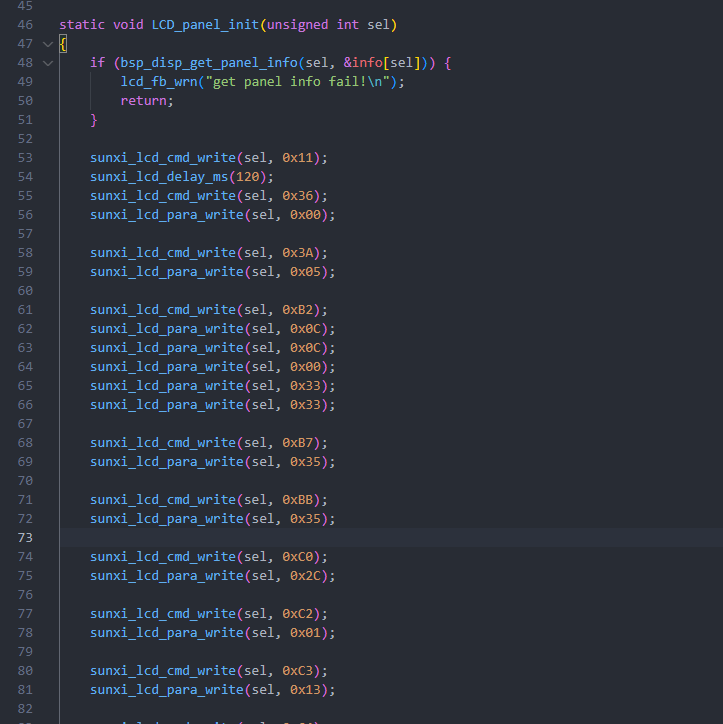

编写初始化序列

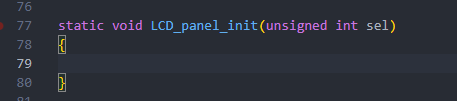

先删除

static void LCD_panel_init(unsigned int sel)中的初始化函数。

然后将屏厂提供的初始化序列复制进来

然后按照

spi_lcd框架的接口改写驱动接口,具体接口如下屏厂函数 SPILCD框架接口 LCD_WR_REGsunxi_lcd_cmd_writeLCD_WR_DATA8sunxi_lcd_para_writedelay_mssunxi_lcd_delay_ms可以直接进行替换

完成后如下

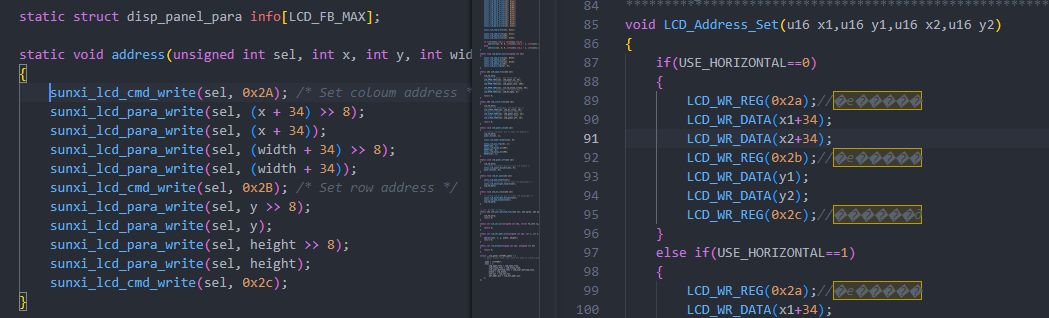

然后对照屏厂提供的驱动修改

address函数

做如下修改

static void address(unsigned int sel, int x, int y, int width, int height) { sunxi_lcd_cmd_write(sel, 0x2A); /* Set coloum address */ sunxi_lcd_para_write(sel, (x + 34) >> 8); sunxi_lcd_para_write(sel, (x + 34)); sunxi_lcd_para_write(sel, (width + 34) >> 8); sunxi_lcd_para_write(sel, (width + 34)); sunxi_lcd_cmd_write(sel, 0x2B); /* Set row address */ sunxi_lcd_para_write(sel, y >> 8); sunxi_lcd_para_write(sel, y); sunxi_lcd_para_write(sel, height >> 8); sunxi_lcd_para_write(sel, height); sunxi_lcd_cmd_write(sel, 0x2c); }完成驱动如下

#include "st7789v.h" static void LCD_power_on(u32 sel); static void LCD_power_off(u32 sel); static void LCD_bl_open(u32 sel); static void LCD_bl_close(u32 sel); static void LCD_panel_init(u32 sel); static void LCD_panel_exit(u32 sel); #define RESET(s, v) sunxi_lcd_gpio_set_value(s, 0, v) #define power_en(sel, val) sunxi_lcd_gpio_set_value(sel, 0, val) static struct disp_panel_para info[LCD_FB_MAX]; static void address(unsigned int sel, int x, int y, int width, int height) { sunxi_lcd_cmd_write(sel, 0x2A); /* Set coloum address */ sunxi_lcd_para_write(sel, (x + 34) >> 8); sunxi_lcd_para_write(sel, (x + 34)); sunxi_lcd_para_write(sel, (width + 34) >> 8); sunxi_lcd_para_write(sel, (width + 34)); sunxi_lcd_cmd_write(sel, 0x2B); /* Set row address */ sunxi_lcd_para_write(sel, y >> 8); sunxi_lcd_para_write(sel, y); sunxi_lcd_para_write(sel, height >> 8); sunxi_lcd_para_write(sel, height); sunxi_lcd_cmd_write(sel, 0x2c); } static void LCD_panel_init(unsigned int sel) { if (bsp_disp_get_panel_info(sel, &info[sel])) { lcd_fb_wrn("get panel info fail!\n"); return; } sunxi_lcd_cmd_write(sel, 0x11); sunxi_lcd_delay_ms(120); sunxi_lcd_cmd_write(sel, 0x36); sunxi_lcd_para_write(sel, 0x00); sunxi_lcd_cmd_write(sel, 0x3A); sunxi_lcd_para_write(sel, 0x05); sunxi_lcd_cmd_write(sel, 0xB2); sunxi_lcd_para_write(sel, 0x0C); sunxi_lcd_para_write(sel, 0x0C); sunxi_lcd_para_write(sel, 0x00); sunxi_lcd_para_write(sel, 0x33); sunxi_lcd_para_write(sel, 0x33); sunxi_lcd_cmd_write(sel, 0xB7); sunxi_lcd_para_write(sel, 0x35); sunxi_lcd_cmd_write(sel, 0xBB); sunxi_lcd_para_write(sel, 0x35); sunxi_lcd_cmd_write(sel, 0xC0); sunxi_lcd_para_write(sel, 0x2C); sunxi_lcd_cmd_write(sel, 0xC2); sunxi_lcd_para_write(sel, 0x01); sunxi_lcd_cmd_write(sel, 0xC3); sunxi_lcd_para_write(sel, 0x13); sunxi_lcd_cmd_write(sel, 0xC4); sunxi_lcd_para_write(sel, 0x20); sunxi_lcd_cmd_write(sel, 0xC6); sunxi_lcd_para_write(sel, 0x0F); sunxi_lcd_cmd_write(sel, 0xD0); sunxi_lcd_para_write(sel, 0xA4); sunxi_lcd_para_write(sel, 0xA1); sunxi_lcd_cmd_write(sel, 0xD6); sunxi_lcd_para_write(sel, 0xA1); sunxi_lcd_cmd_write(sel, 0xE0); sunxi_lcd_para_write(sel, 0xF0); sunxi_lcd_para_write(sel, 0x00); sunxi_lcd_para_write(sel, 0x04); sunxi_lcd_para_write(sel, 0x04); sunxi_lcd_para_write(sel, 0x04); sunxi_lcd_para_write(sel, 0x05); sunxi_lcd_para_write(sel, 0x29); sunxi_lcd_para_write(sel, 0x33); sunxi_lcd_para_write(sel, 0x3E); sunxi_lcd_para_write(sel, 0x38); sunxi_lcd_para_write(sel, 0x12); sunxi_lcd_para_write(sel, 0x12); sunxi_lcd_para_write(sel, 0x28); sunxi_lcd_para_write(sel, 0x30); sunxi_lcd_cmd_write(sel, 0xE1); sunxi_lcd_para_write(sel, 0xF0); sunxi_lcd_para_write(sel, 0x07); sunxi_lcd_para_write(sel, 0x0A); sunxi_lcd_para_write(sel, 0x0D); sunxi_lcd_para_write(sel, 0x0B); sunxi_lcd_para_write(sel, 0x07); sunxi_lcd_para_write(sel, 0x28); sunxi_lcd_para_write(sel, 0x33); sunxi_lcd_para_write(sel, 0x3E); sunxi_lcd_para_write(sel, 0x36); sunxi_lcd_para_write(sel, 0x14); sunxi_lcd_para_write(sel, 0x14); sunxi_lcd_para_write(sel, 0x29); sunxi_lcd_para_write(sel, 0x32); sunxi_lcd_cmd_write(sel, 0x21); sunxi_lcd_cmd_write(sel, 0x11); sunxi_lcd_delay_ms(120); sunxi_lcd_cmd_write(sel, 0x29); if (info[sel].lcd_x < info[sel].lcd_y) address(sel, 0, 0, info[sel].lcd_x - 1, info[sel].lcd_y - 1); else address(sel, 0, 0, info[sel].lcd_y - 1, info[sel].lcd_x - 1); } static void LCD_panel_exit(unsigned int sel) { sunxi_lcd_cmd_write(sel, 0x28); sunxi_lcd_delay_ms(20); sunxi_lcd_cmd_write(sel, 0x10); sunxi_lcd_delay_ms(20); sunxi_lcd_pin_cfg(sel, 0); } static s32 LCD_open_flow(u32 sel) { lcd_fb_here; /* open lcd power, and delay 50ms */ LCD_OPEN_FUNC(sel, LCD_power_on, 50); /* open lcd power, than delay 200ms */ LCD_OPEN_FUNC(sel, LCD_panel_init, 200); LCD_OPEN_FUNC(sel, lcd_fb_black_screen, 50); /* open lcd backlight, and delay 0ms */ LCD_OPEN_FUNC(sel, LCD_bl_open, 0); return 0; } static s32 LCD_close_flow(u32 sel) { lcd_fb_here; /* close lcd backlight, and delay 0ms */ LCD_CLOSE_FUNC(sel, LCD_bl_close, 50); /* open lcd power, than delay 200ms */ LCD_CLOSE_FUNC(sel, LCD_panel_exit, 10); /* close lcd power, and delay 500ms */ LCD_CLOSE_FUNC(sel, LCD_power_off, 10); return 0; } static void LCD_power_on(u32 sel) { /* config lcd_power pin to open lcd power0 */ lcd_fb_here; power_en(sel, 1); sunxi_lcd_power_enable(sel, 0); sunxi_lcd_pin_cfg(sel, 1); RESET(sel, 1); sunxi_lcd_delay_ms(100); RESET(sel, 0); sunxi_lcd_delay_ms(100); RESET(sel, 1); } static void LCD_power_off(u32 sel) { lcd_fb_here; /* config lcd_power pin to close lcd power0 */ sunxi_lcd_power_disable(sel, 0); power_en(sel, 0); } static void LCD_bl_open(u32 sel) { sunxi_lcd_pwm_enable(sel); /* config lcd_bl_en pin to open lcd backlight */ sunxi_lcd_backlight_enable(sel); lcd_fb_here; } static void LCD_bl_close(u32 sel) { /* config lcd_bl_en pin to close lcd backlight */ sunxi_lcd_backlight_disable(sel); sunxi_lcd_pwm_disable(sel); lcd_fb_here; } /* sel: 0:lcd0; 1:lcd1 */ static s32 LCD_user_defined_func(u32 sel, u32 para1, u32 para2, u32 para3) { lcd_fb_here; return 0; } static int lcd_set_var(unsigned int sel, struct fb_info *p_info) { return 0; } static int lcd_set_addr_win(unsigned int sel, int x, int y, int width, int height) { address(sel, x, y, width, height); return 0; } static int lcd_blank(unsigned int sel, unsigned int en) { return 0; } struct __lcd_panel st7789v_panel = { /* panel driver name, must mach the name of lcd_drv_name in sys_config.fex */ .name = "st7789v", .func = { .cfg_open_flow = LCD_open_flow, .cfg_close_flow = LCD_close_flow, .lcd_user_defined_func = LCD_user_defined_func, .blank = lcd_blank, .set_var = lcd_set_var, .set_addr_win = lcd_set_addr_win, }, };对接驱动框架

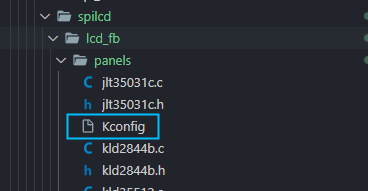

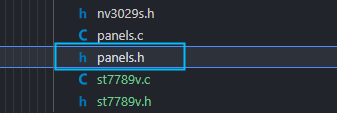

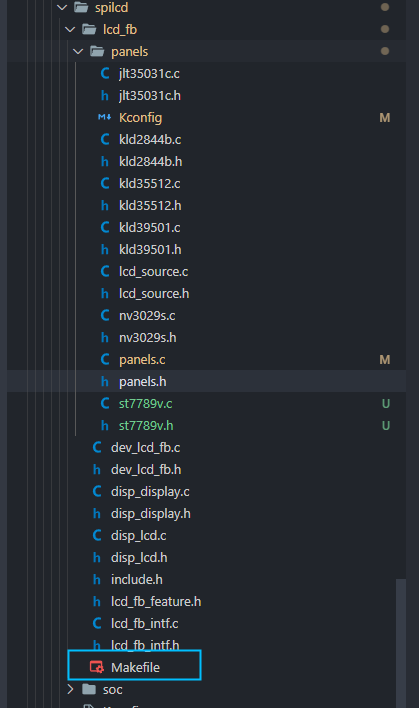

完成了屏幕驱动的编写,接下来需要对接到 SPILCD 驱动框架。首先编辑

Kconfig

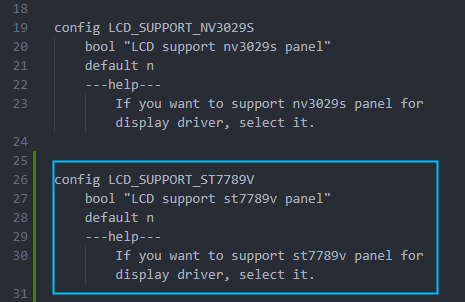

增加

st7789v的配置

config LCD_SUPPORT_ST7789V bool "LCD support st7789v panel" default n ---help--- If you want to support st7789v panel for display driver, select it.然后编辑

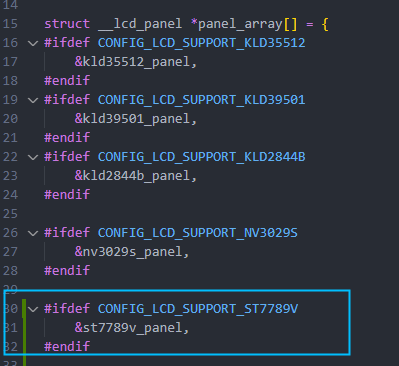

panels.c在panel_array里增加st7789驱动的引用

如下图

#ifdef CONFIG_LCD_SUPPORT_ST7789V &st7789v_panel, #endif之后编辑

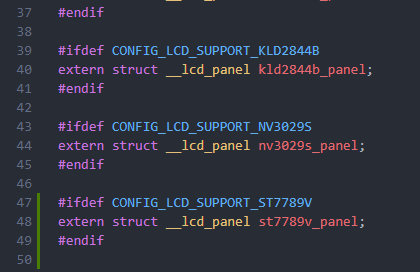

panels.h同样增加引用

如下图

#ifdef CONFIG_LCD_SUPPORT_ST7789V extern struct __lcd_panel st7789v_panel; #endif最后编辑外层的

Makefile增加编译选项

如下所示

obj-${CONFIG_LCD_SUPPORT_ST7789V} += panels/st7789v.o选择 ST7789V 驱动

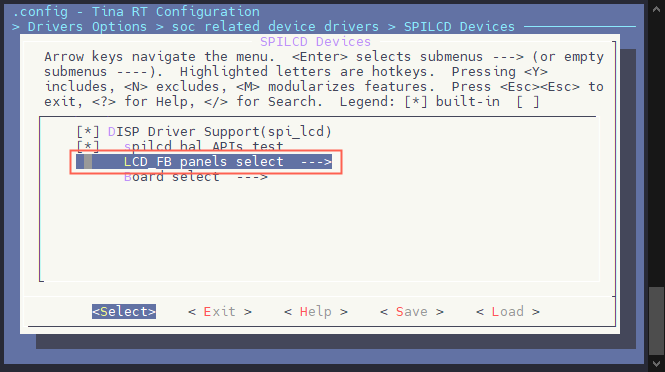

在 SPILCD 驱动选择界面可以看到

LCD_FB panels select选择 SPI 屏幕的驱动进入

LCD_FB panels select选项

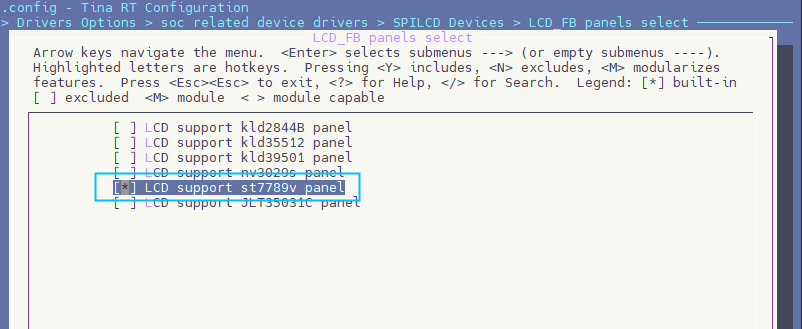

选择并勾选

[*] LCD support st7789v panel

配置 SPI LCD 引脚

打开你喜欢的编辑器,修改文件:

board/r128s2/module/configs/sys_config.fex[lcd_fb0] lcd_used = 1 lcd_model_name = "spilcd" lcd_driver_name = "st7789v" lcd_x = 172 lcd_y = 320 lcd_width = 17 lcd_height = 32 lcd_data_speed = 50 lcd_pwm_used = 1 lcd_pwm_ch = 1 lcd_pwm_freq = 5000 lcd_pwm_pol = 0 lcd_if = 0 lcd_pixel_fmt = 11 lcd_dbi_fmt = 2 lcd_dbi_clk_mode = 1 lcd_dbi_te = 1 fb_buffer_num = 2 lcd_dbi_if = 4 lcd_rgb_order = 0 lcd_fps = 60 lcd_spi_bus_num = 1 lcd_frm = 2 lcd_gamma_en = 1 lcd_backlight = 100 lcd_power_num = 0 lcd_gpio_regu_num = 0 lcd_bl_percent_num = 0 lcd_spi_dc_pin = port:PA19<1><0><3><0> ;RESET Pin lcd_gpio_0 = port:PA20<1><0><2><0>编译打包

运行命令

mp编译打包,可以看到编译了st7789v.o

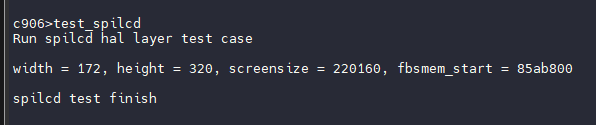

测试

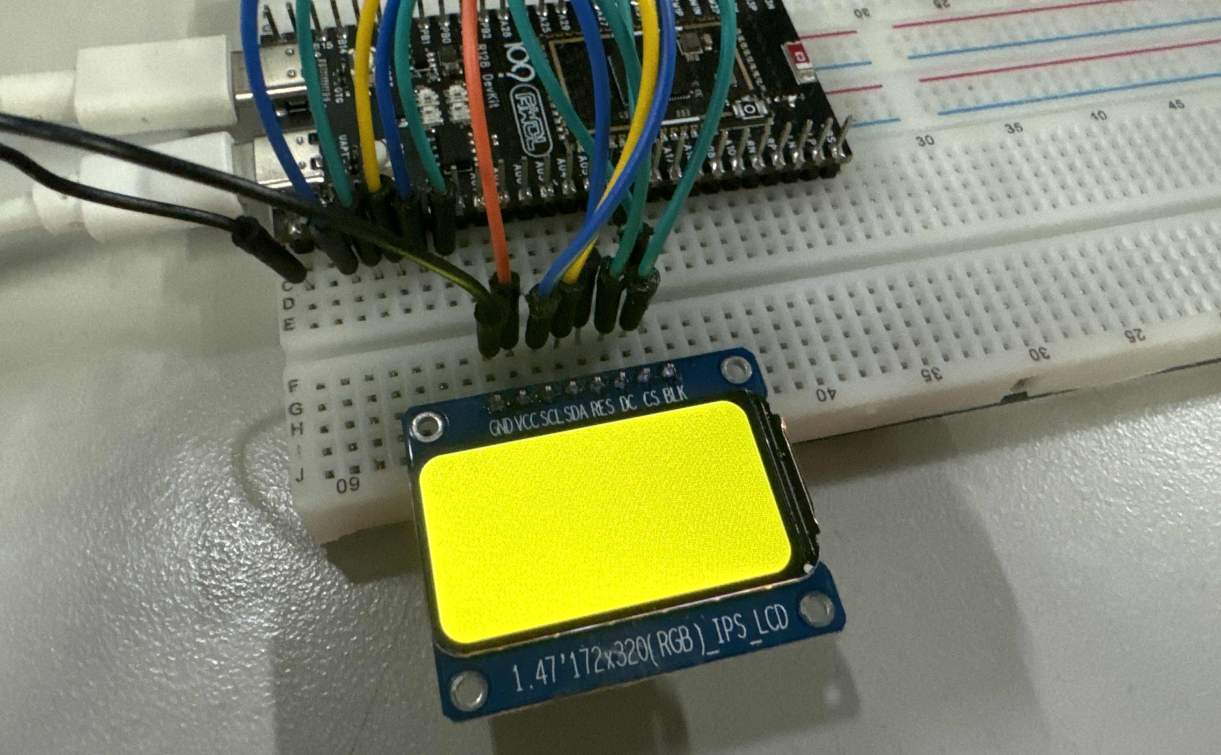

烧录启动之后,屏幕背光启动,但是屏幕全黑。

输入

test_spilcd,屏幕显示黄色。

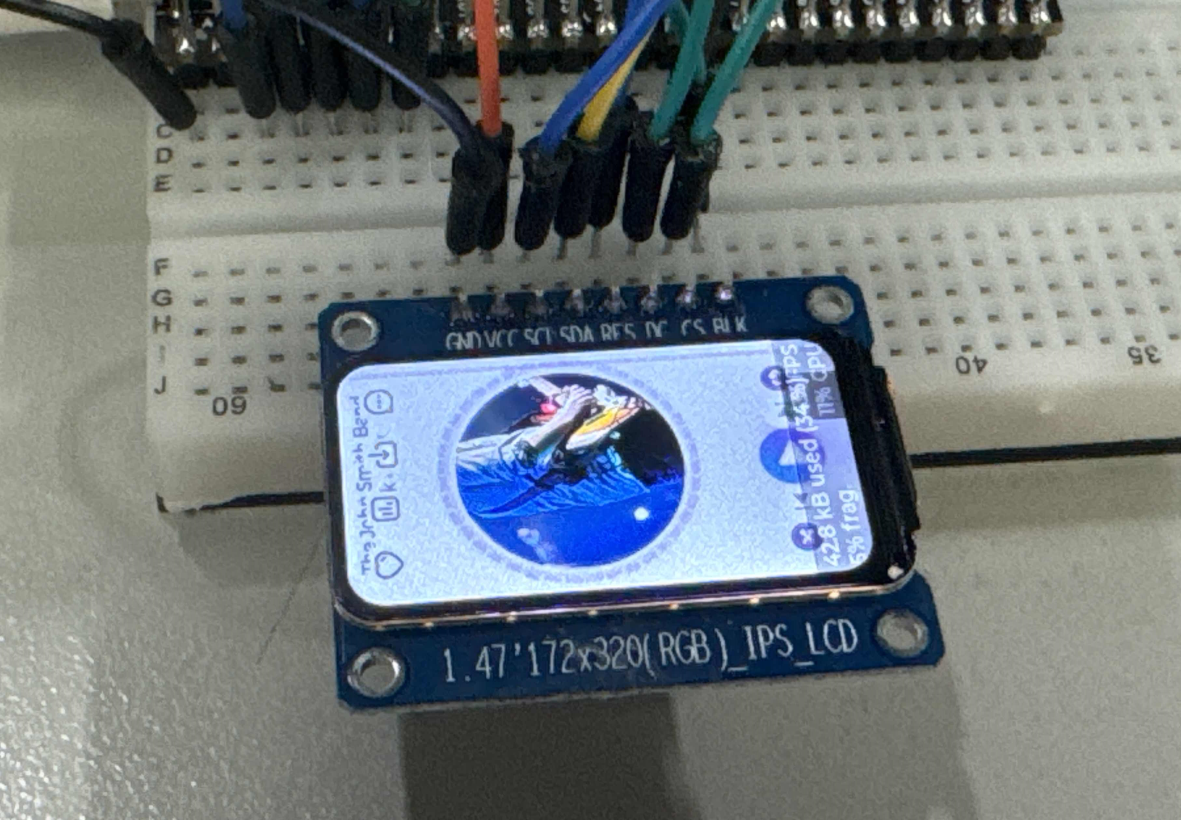

输入

lv_examples 1可以显示lvgl界面

常见问题

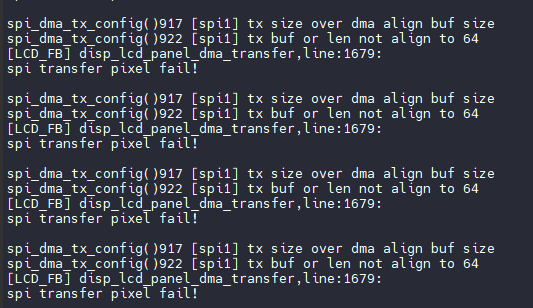

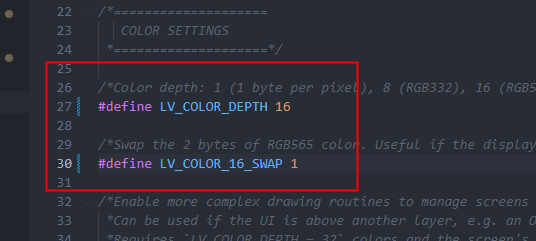

LVGL 出现 DMA Over Size

这是由于 LVGL 配置的

LV_COLOR_DEPTH为 32,但是 SPI 屏配置为16位。请修改lv_conf.h

Copyright © 2024 深圳全志在线有限公司 粤ICP备2021084185号 粤公网安备44030502007680号